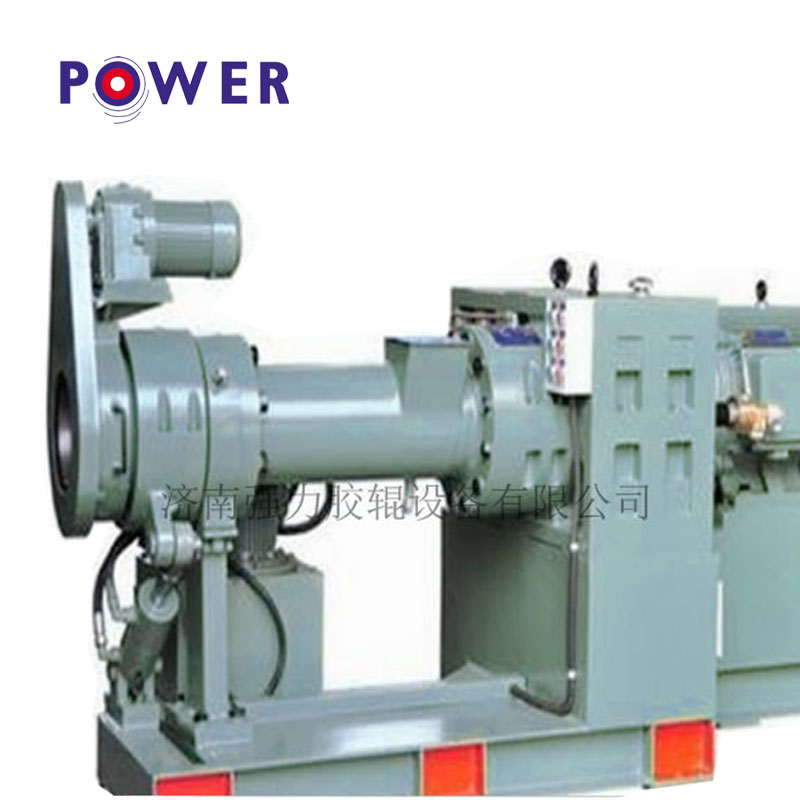

Roj Hmab Lim / Roj Hmab Strainer

Xaiv cov roj hmab lim

1. Kev siv roj hmab lim - haum rau cov roj hmab muag muag sib xyaw uas tsis xav Remix.

Nta: Yooj yim los ntxuav, tuaj yeem kaw dua 200 mus kom ntev lim, tso tawm loj dua.

2. Ntsia thawv roj hmab lim - haum rau txhua hom roj hmab sib txuas rau cov menyuam kev lag luam.

Nta: Cov ntau ntawm cov roj hmab sib txuas tuaj yeem lim.

1) tib ntsia hlau hom:

Tus qauv sib dhos - haum rau compound ntawm 25-95sh-a, tab sis tsis yog rau siab viscosity roj hmab, xws li silicon thiab lwm yam.

Siv cov ntsia hlau ib qho - Haum rau txhua hom roj hmab sib txuas ntawm 25, ay yog rau siab viscosity roj hmab, xws li silicon, epdm, hypalon, thiab lwm yam.

2) Dual-Ntsia Hlau Hom:

Kav Tswj Xyuas Dual-Hlau Hom - Tsim rau txhua hom roj hmab sib txuas ntawm 25, txawm tias rau cov roj hmab uas siab tshaj, EPDM, hypalon, thiab lwm yam.

Kav Tswj Xyuas Dual-Ntsia Hlau Nrog TCU Hom - Haum rau compound ntawm 25-100Sh-A, Qhov tshwj xeeb tshaj yog haum rau kev kub taub hau.

| Dual-Ntsia Hlau Roj Hmab Lim Parameter | |||||

| Hom / Series | φ115 hom | Hom haujlwm AB150 | IT200 Hom | Tshuab + Hom | φ300 hom |

| Ntsia Hlau Kab Ciam (Mm) | 115 | 150 | 200 | 250 | 300 |

| Reducer Cov Lus Qhia Tshwj Xeeb | 225 iav kem | 250 iav lub thawv | 280 iav lub thawv | 330 iav iav | 375 iav lub thawv |

| Ntev-txoj kab uas hla ntawm cov ntsia hlau (l / d) | 6:01 | 1.8: 1 | 2.7: 1 | 3.6: 1 | 3.6: 1 |

| Ntsia hlau siab tshaj (RPM) | 45 | 45 | 40 | 40 | 35 |

| Lub cev muaj zog (KW) | 45 | 45 ~ 55 | 70 ~ 90 | 90 ~ 110 | 130 ~ 160 |

| Fais fab voltage (v) | 380 | 380 | 380 | 380 | 380 |

| Qhov tsim nyog tshaj plaws (Kg / teev) | 240 | 300 | 355 | 445 | 465 |

| Chav ua tub yees cov hluav taws xob compressor zog | 5P | 5P | 5P | 7.5p | 7.5p |

Xaiv qhov ntev-txoj kab uas hla:

1. Yog tias muaj cov xuab zeb nyob hauv cov roj hmab, qhov ntev-txoj kab uas hla ntawm cov ntsia hlau yuav tsum tau xaiv rau ib qho loj dua.

2. Qhov zoo ntawm qhov loj ntev-txoj kab ntawm cov ntsia hlau yog qhov ua haujlwm tau yooj yim, cov roj hmab yog cov khoom siv tau zoo thiab cov khoom zoo yog qhov zoo. Txawm li cas los xij, yog tias cov ntsia hlau ntev, nws yuav yooj yim ua rau cov roj hmab hlawv, thiab cov ntsia hlau ua yog qhov nyuaj, thiab muaj zog extrusion yog nce.

3. Lub hau ntswj siv rau cov tshuaj kub pub rau cov roj hmab tshuab feem ntau yuav siv sijhawm ntev-lub taub rau cov roj hmab tshuab ntsuas ntawm 8 txog 12 zaug.

Qhov zoo ntawm kev nce siab ntev-diam piv

1) Lub hau ntswj yog tag nrho cov khoom siv, thiab lub cev thiab cov kws kho mob ntawm cov khoom tuaj yeem txhim kho.

2) Zoo siv cov khoom siv thiab cov tsos zoo ntawm cov khoom lag luam.

3) nce cov ntawv sau ntxiv ntawm 20-40%. Nyob rau tib lub sijhawm, cov xeeb ceem nkhaus ntawm cov ntsia hlau nrog loj ntev-digin muaj qhov nqes qis, thiab ruaj khov extrusion ntim.

4) Zoo rau hmoov moulding, xws li PVC hmoov extrusion raj.

Qhov tsis zoo ntawm kev nce ntev-diamer piv:

Kev nce ntev ntev-lub cheeb piv ua rau tsim cov ntsia hlau thiab cov sib dhos ntawm ntsia hlau thiab barrel nyuaj. Yog li ntawd, qhov ntev-txoj kab uas hla tsis tau muaj kev nce siab yam tsis muaj kev txwv.

Qho kev pab

1. Kev pabcuam kev pabcuam.

2. Txij Nkawm Kev Pabcuam.

3. Kev txhawb pab online kev pabcuam muab rau.

4. Kev pabcuam cov ntaub ntawv cov ntaub ntawv muab.

5. On-rorte rest service muab.

6. Kev hloov chaw kho thiab kho cov kev pabcuam.