Cov txheej txheem ntau lawm ntawm cov roj hmab nqa khoom feem ntau ua ntej ntau kauj ruam, suav nrog kev npaj cov roj hmab roj hmab, molding roj hmab chais, thiab kev kho kom nto. Txog tam sim no, feem ntau cov lag luam tseem cia siab rau kev tuav sibter nyob rau hauv ntau lawm. Nyob rau hauv xyoo tsis ntev los no, nrog kev txhim kho kev txhaj tshuaj, extrusion, roj hmab cov khoom siv tau tso roj hmab thiab cov roj hmab tso rau ntawm txoj kab nrawm ntawm kev siv tsheb thiab kev siv tshuab. Yog li, kev tsim khoom txuas ntxiv los ntawm cov roj hmab khoom rau moulding thiab vulcanization cov txheej txheem tau ua tiav, nce zuj zus kev ua haujlwm ib puag ncig thiab kev siv zog ua haujlwm. Vim tias tsis muaj peev xwm ntawm ib qho impurities, cov pob zeb, thiab cov npuas ntawm cov roj hmab ntawm cov roj hmab cov menyuam, cov kab nrib pleb, kab nrib pleb Yog li ntawd, tsuas yog los ntawm kev khaws cov roj hmab rollers kiag li huv thiab ua tiav cov txheej txheem ua haujlwm, ua tiav cov haujlwm ua haujlwm thiab cov cuab yeej siv tau zoo tshaj plaws hauv kev ruaj khov ntawm cov khoom lag luam tsis ruaj khov. Tam sim no, kev sib xyaw ua ke, kev txhaj tshuaj molding, volcanization thiab sib tsoo roj hmab thiab hlau cores tau dhau los ua cov txheej txheem tech.

Kev npaj ntawm cov roj hmab khoom siv rau roj hmab cov menyuam cov txheej txheem

Rau cov roj hmab chais, cov sib xyaw ntawm cov khoom siv roj hmab yog qhov tseem ceeb tshaj plaws. Muaj ntau tshaj 10 hom roj hmab cov ntaub ntawv siv rau cov roj hmab chais, xws li roj hmab muaj cov roj hmab tshwj xeeb, nrog rau cov roj hmab ntawm cov av tshwj xeeb (0-90) degrees. Cov txheej txheem sib xyaw yog kom siv qhib cov tshuab roj hmab sib tov kom sib xyaw thiab cov txheej txheem ntau hom Master roj hmab tebchaw. Lub tshuab siv roj hmab sib xyaw ua ke yog ib hom roj hmab sib xyaw ua ke los npaj cov roj hmab sib xyaw los yog ua kom siv tau kub, cov menyuam ntsuas,Yas kho kom zoo, thiab molding rau cov khoom siv roj hmab. Txawm li cas los xij, cov no yog hom ntawm kev sib xyaw cov khoom siv yas. In recent years, enterprises have increasingly switched to using meshing internal mixers to produce rubber materials through segmented mixing.

Tom qab ua tiav cov khoom siv sib xyaw ua ke, cov roj hmab khoom siv yuav tsum tau lim siv cov tshuab lim roj hmab los tshem tawm cov khoom siv hluav taws xob hauv cov khoom siv roj hmab. Tom qab ntawd siv tus calender, extruder, thiab laminating tshuab ua ib zaj duab xis los yog sawb tsis muaj npuas los yog impurities, uas yog siv rau kev sib sau roj hmab chais. Ua ntej kev sib sau, kev soj ntsuam nruj me ntsis yuav tsum tau nqa tawm ntawm cov yeeb yaj kiab thiab cov roj hmab yuav tsum tau khaws cia tshiab kom tiv thaiv adhesion thiab compression deformation. Cov txheej txheem sib txawv ntawm cov yeeb yaj kiab thiab cov roj hmab ib txwm yuav tsum tsis muaj cov impurities thiab bubbles, txwv tsis pub cov xuab zeb yuav tshwm sim thaum sib tsoo lub ntsej muag tom qab vulcanization.

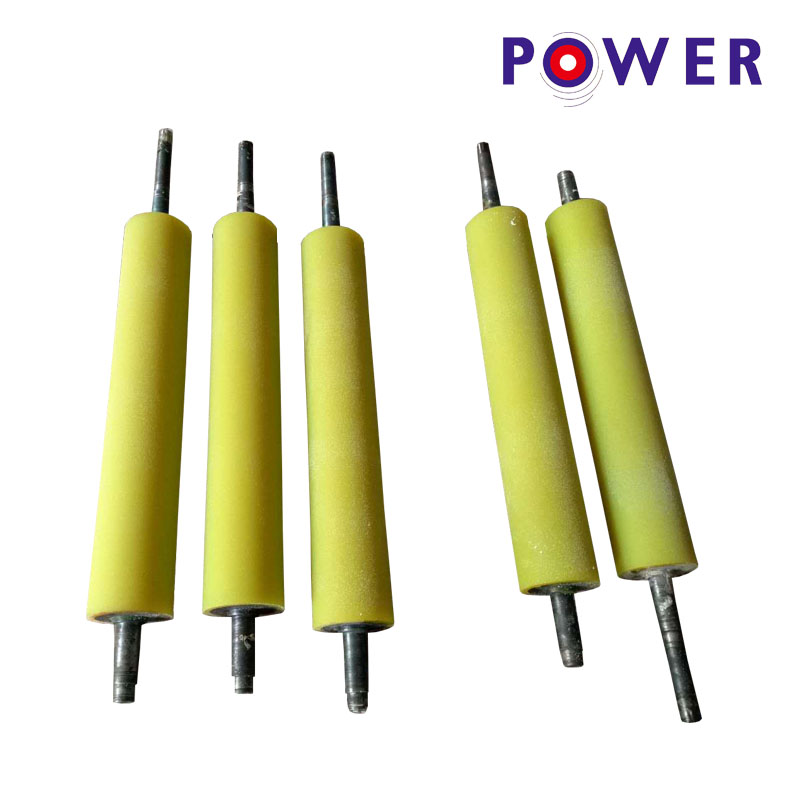

Roj Hmab Rau Cov Khaub Ncaws Sib Nraus Hauv Cov Txheej Txheem Tsim Khoom Ntawm Roj Hmab Chais

Moulding ntawm roj hmab chais feem ntau tsuas yog cuam tshuam nrog kev tso nplaum thiab wrapping roj hmab ntawm cov hlau core. Cov hau kev sib xws suav nrog kev qhwv, extrusion, moulding, txhaj tshuaj moulding, thiab txhaj tshuaj moulding. Tam sim no, feem ntau hauv kev lag luam hauv tsev feem ntau cia siab rau cov neeg kho tshuab lossis phau ntawv sib txuas lus moulding, thaum feem ntau cov teb chaws txawv teb chaws tau ua tiav tshuab automation. Cov khoom lag luam loj thiab nruab nrab tsim khoom lag luam kom tsis txhob muaj cov qauv ntawm kev sib txuas nrog cov phuam qhwv cajdab tsis tu ncua thiab daim ntawv looj roj hmab txuas ntxiv mus qhwv thiab tsim kev ntau lawm. Nyob rau tib lub sijhawm, thaum lub sij hawm moulding txheej txheem, cov kev qhia tshwj xeeb, thiab cov tsos pom tau tswj los ntawm ib micocomputer, cov menyuam Suav,Thiab qee tus kuj tseem tuaj yeem siv tau siv lub kaum sab xis thiab tsis xwm yeem extrusion txoj kev ntawm extruder.

Kev siv kev ua kom haum thiab Microcomputer tsis siv neeg tswj cov txheej txheem tuaj yeem tshem tawm cov npuas thiab txo qis kev ua haujlwm rau qhov ua tau zoo tshaj plaws. Txhawm rau tiv thaiv deformation thaum lub sij hawm vulcanization ntawm cov roj hmab cov menyuam thiab tiv thaiv cov khoom ntawm npuas thiab kab laug, Hina Roj Hmab Corona kev cai,Txoj kev hloov tau yooj yim yuav tsum tau siv sab nraud rau cov txheej txheem moulding ntawm txoj kev qhwv. Feem ntau, muaj ntau txheej ntawm paj rwb lossis nylon ntaub qhwv ib ncig ntawm cov npoo ntawm cov roj hmab cov menyuam, roj hmab yob cov chav tua nyuaj,Thiab tom qab ntawd tsau thiab nias nrog hlau xaim lossis cov hlua fiber.

Rau cov roj hmab me thiab micro roj hmab chais, ntau cov txheej txheem ua ke xws li kev ua zes, txhaj tshuaj moulding, txhaj tshuaj moulding, thiab hliv tuaj yeem siv. Txhawm rau txhim kho ntau lawm, molding cov txheej txheem tam sim no siv tau feem ntau siv, thiab qhov raug yog ntau dua li cov txheej txheem moulding. Kev txhaj tshuaj thiab nias ntawm cov roj hmab khov, nrog rau cov pouring kua roj hmab ua kua, tau dhau los ua cov txheej txheem ntau tshaj plaws.

Lub Sijhawm Post: Jul-25-2024