1, stripping tshuab

Lub Universal Hom PCM series stripping tshuab yog tsim los npaj cov roj hmab siv qub roj hmab rau cov txheej txheem npog. Cov cuab yeej xa rov qab tau muab lub nplhaib txiav tawm thiab tso cai rau cov abrasive siv tau sander kom tshem tau ob peb txhiab cov ntaub ntawv kawg. Thaum cov nplaim xwm tau npaj tau zoo koj tuaj yeem ua rau lub sijhawm thaum cov khoom siv PCM. PCM hloov cov txheej txheem sandblasting nrog cov pa phem ib puag ncig. (Peb tsis pom zoo kom siv)

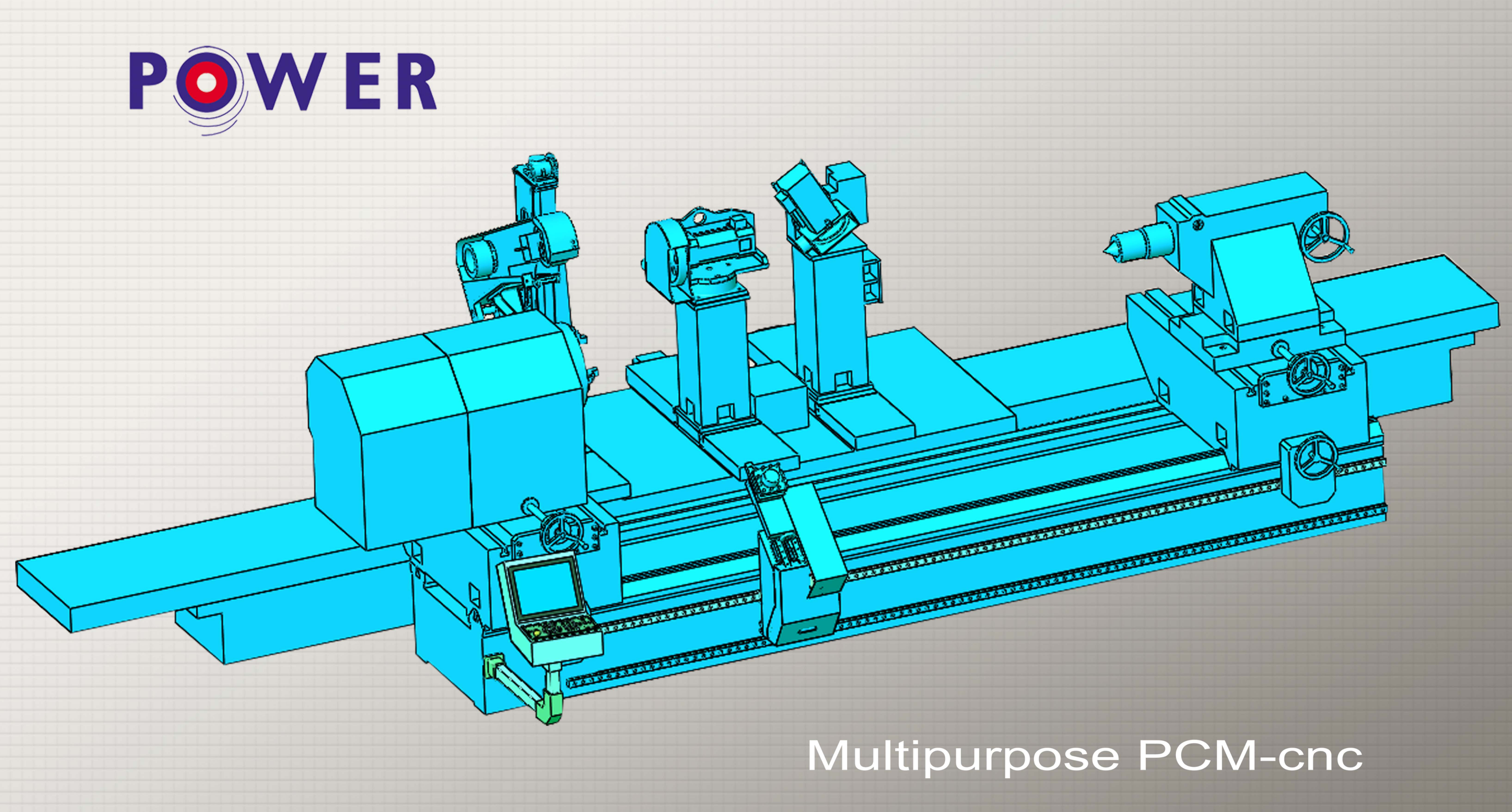

2, Multifunununctional pcm-CNC: (Peb pom zoo kom siv)

PCM-cnc multifunctional thiab muaj ntau lub hom phiaj cov menyuam sib tsoo tshuab yog kev lag luam sib tsoo tshuab. Nws tsis tuaj yeem tsuas yog siv cov roj hmab qub roj hmab ua ntej npog cov roj hmab, tab sis kuj tseem ua cov roj hmab ua tom qab vulcanization, thiab tuaj yeem ua ntau hom duab puab txuas rau ntawm cov npoo roj hmab. Txo lub siab rau cov khoom siv ntsuas hluav taws xob, txhim kho cov nqi ntau lawm, thiab cov nqi ntau lawm.

Lub hom phiaj:

1. Kev ua cov menyuam cov menyuam ua ntej vov roj ua ntej vov roj hmab, polishing cov menyuam cov xo siab, thiab txhuam cov nplaum.

2. Hnov Machining tom qab vulcanization, nruab nrog lub tig tig los tshem tawm cov tshaj tom qab vertolanization;

3. Nruab nrog tshwj xeeb alloy sib tsoo log rau elastomers ntxhib sib tsoo. Kev ntxhib machining ua ntej precision machisent yog ceev vim tias tsis muaj qhov yuav tsum muaj qhov yuav tsum muaj rau ntxhib machining.

4. Paub tias grooves ntawm ntau yam duab.

Nta:

1. Qib siab ntawm kev siv tshuab thiab kev ua haujlwm yooj yim.

2. Vim nws cov qauv hlau steel, nws yog cov khoom lag luam tsim khoom siv rau kev sib ntsib ntxhib machining thiab tshwj xeeb xav tau

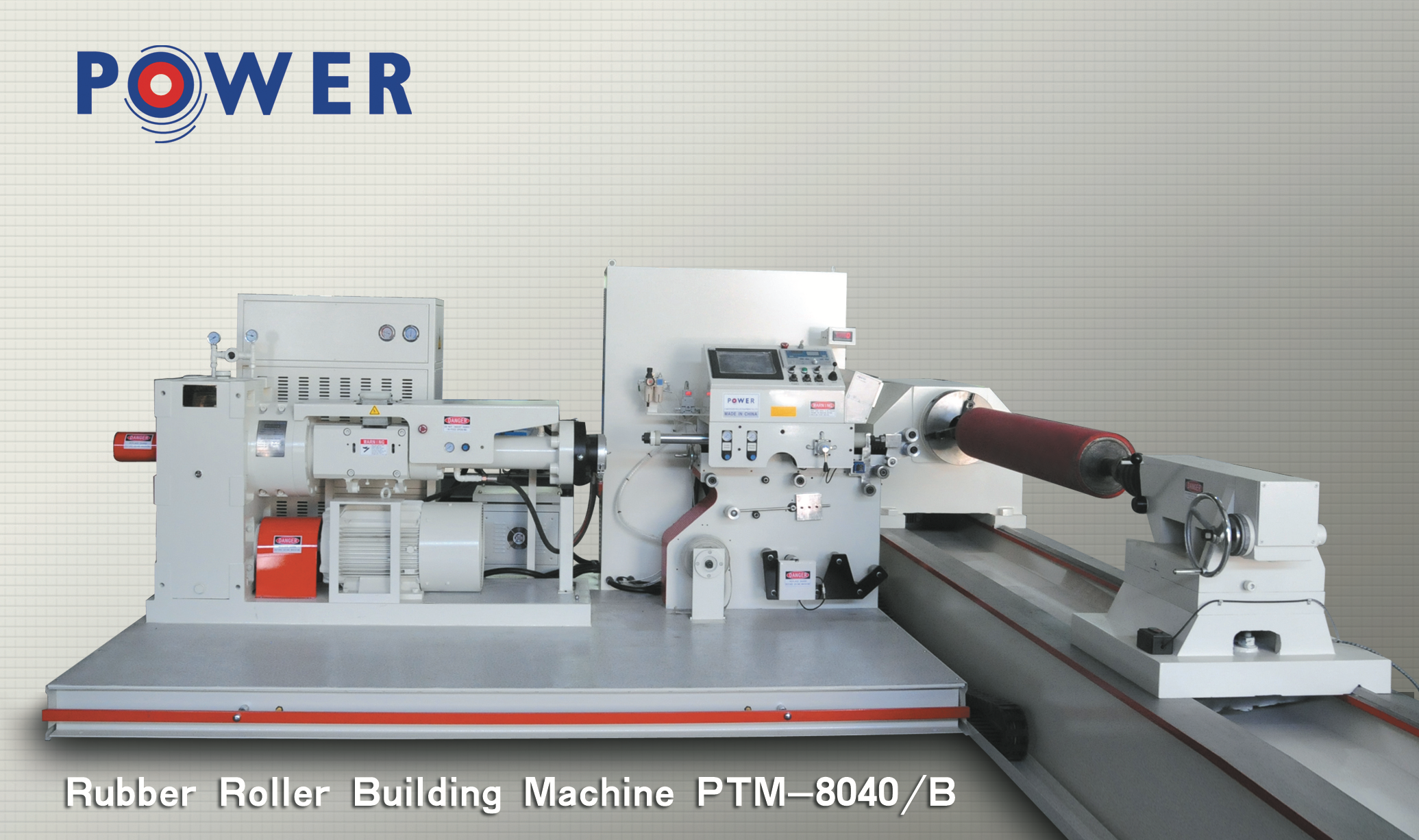

3,PTM-5040 (nruab nrab loj) roj hmab npog tshuab

(Txheej txheem / hom kev lag luam)

PTM ntawmmEdium loj yog tsim rau roj hmab chais hauv luam ntawv, ntim, textile thiab steel Industries. Lub kov kov tshuaj ntsuam kev ua haujlwm tau raws li peb cov kev xav tau. Daim ntawv npog yog tsuas yog los ntawm lub tiaj npog.

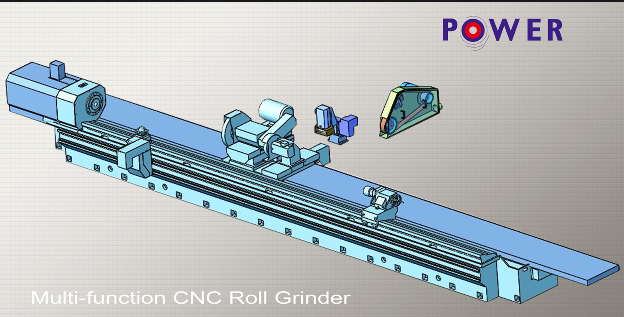

4, mQhov kawg-ua haujlwm yob li

Multi-functional nruab nrab loj roj hmab hluav taws xob cov roj sib tsoo tshuab yog cov cuab yeej nyiam rau kev txhim kho ib puag ncig thiab nce ntau dua kev ua haujlwm. Nws sib xyaw ntau cov txheej txheem ntau lawm rau hauv ib qho, txo cov kev sib txuas thiab kev siv zog ua haujlwm.

Cov haujlwm ntawm PCG suav nrog ob lub rooj nruab nrab nruab nrab mounted ntawm cov khoom txav loj uas tau txav chaw loj carriage rooj. Ib qho nruab nrog cov xuab zeb sib tsoo lub taub hau tshwj xeeb tsim rau cov luam roj hmab yob rau lwm cov pob hluav taws xob thiab cov khoom siv polyoy tuaj yeem sib txuas nrog lub log sib tsoo tsheb ntaus rau kev siv. Cov khoom siv no tsis suav nrog grooving thiab txiav cov cuab yeej.

5,Polishing tshuab

Lub PPM series tuaj yeem txhim kho lub ntsej muag du ntawm cov roj hmab. Qhov no ua tiav los ntawm kev siv cov xuab zeb uas tsim nyog xuab zeb loj, xuab zeb siv tawv siab, thiab txiav txim ceev. Nws yog qhov tsim nyog heev rau cov luam ntawv rau cov luam ntawv nrog lub ntsej muag siab yuav tsum tau ua.

6, pSF laser ntsuas rau chais

Txhawm rau ua haujlwm rau txoj haujlwm no raws li txoj ntsiab cai ntawm cov nqi peev tsawg, nws tuaj yeem nqis peev tom qab.

Lub Sijhawm Post: Nov-15-2024